With over 4,000,000 feet of successfully installed, Permalok® casing pipe is the proven leader for trenchless application of steel pipe. Our patented mechanical press fit interlocking connections join pipe sections quicker than any other system in the field.

2.0 METHODS OF WELL CONSTRUCTION 2.1 Cable Tool There are several methods of drilling water wells today. These relate to particular well design and casing and screen requirements.

Rosie's Gaming features 2,300 state of the art Historical Horse Racing games throughout the Commonwealth of Virginia. Visit one of our locations throughout the year and hit the jackpot.

- Casing shall be manufactured with a threaded joint using a 'V' thread on a thread pattern of 4 threads per inch on a 4 degree taper using 3 inches of threads.

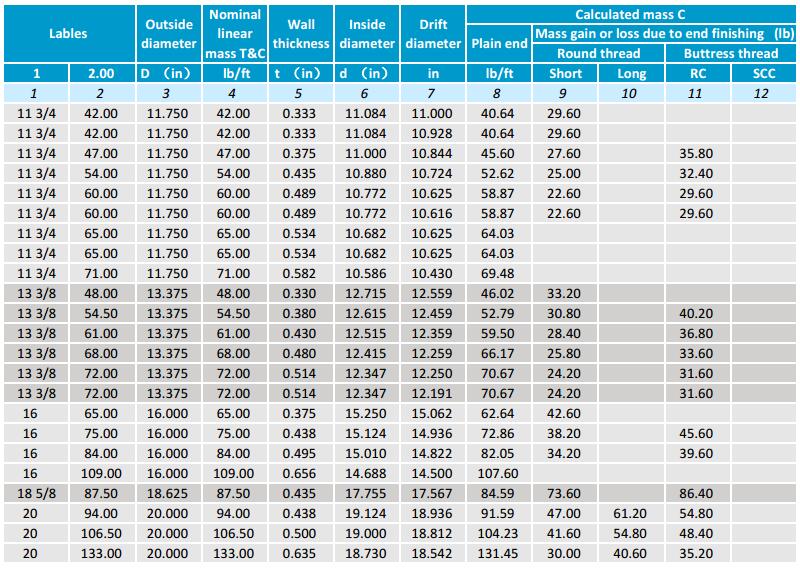

- API CASING TABLE SPECIFICATION Size Wei ght ID Drift Capacity Inches mm lb/ft Inches mm Inches mm bbl/100ft 7 3/4 196.85 46.10 6.560 166.62 6.500 165.10 4.18.

Permalok® Steel Casing Pipe excels in trenchless jacking construction applications including microtunneling and pipe jacking, auger boring, pipe ramming, and others. Our precision machined joint reduces field time by eliminating butt-weld joints, resulting is a shortened tunneling duration and reduced field costs. Casino del sol update. Permalok offers the strength and durability of steel piping with a variety of coating options.

With over 4,000,000 feet of pipe successfully installed in the past 25 years, Permalok® stands as the product of choice for trenchless contractors and engineers on their most challenging and significant projects.

Permalok® steel casing pipe dramatically increases field installation efficiency in trenchless projects. Our engineered systems are available in both rolled and sprialweld construction and utilize a proprietary interlocking joint system that connects pipe quickly and eliminates field butt-welding.

Delivered to your jobsite with an integrated interlocking joint, Permalok® steel casing pipe eliminates time-intensive field butt welds in trenchless pipe installation projects. The precision-machined interface is flush with the interior and exterior surfaces of the pipe for quick alignment and connection. Combined with the use of a silicone sealant, the Permalok joint is leak resistant under the most challenging conditions.

Selecting Permalok® casing pipe over field-welded pipe provides an advantage you can take to the bank. Our proprietary airtight joints seal within minutes, compared to hours reserved for joint welding. The below examples demonstrate real savings in time and money in trenchless installations.

Request a Quote

Need a Permalok quote? Use our easy-to-fill-out form to connect with our sales team.

4 Casing Dimensions

- Casing shall be manufactured with a threaded joint using a 'V' thread on a thread pattern of 4 threads per inch on a 4 degree taper using 3 inches of threads.

- API CASING TABLE SPECIFICATION Size Wei ght ID Drift Capacity Inches mm lb/ft Inches mm Inches mm bbl/100ft 7 3/4 196.85 46.10 6.560 166.62 6.500 165.10 4.18.

Permalok® Steel Casing Pipe excels in trenchless jacking construction applications including microtunneling and pipe jacking, auger boring, pipe ramming, and others. Our precision machined joint reduces field time by eliminating butt-weld joints, resulting is a shortened tunneling duration and reduced field costs. Casino del sol update. Permalok offers the strength and durability of steel piping with a variety of coating options.

With over 4,000,000 feet of pipe successfully installed in the past 25 years, Permalok® stands as the product of choice for trenchless contractors and engineers on their most challenging and significant projects.

Permalok® steel casing pipe dramatically increases field installation efficiency in trenchless projects. Our engineered systems are available in both rolled and sprialweld construction and utilize a proprietary interlocking joint system that connects pipe quickly and eliminates field butt-welding.

Delivered to your jobsite with an integrated interlocking joint, Permalok® steel casing pipe eliminates time-intensive field butt welds in trenchless pipe installation projects. The precision-machined interface is flush with the interior and exterior surfaces of the pipe for quick alignment and connection. Combined with the use of a silicone sealant, the Permalok joint is leak resistant under the most challenging conditions.

Selecting Permalok® casing pipe over field-welded pipe provides an advantage you can take to the bank. Our proprietary airtight joints seal within minutes, compared to hours reserved for joint welding. The below examples demonstrate real savings in time and money in trenchless installations.

Request a Quote

Need a Permalok quote? Use our easy-to-fill-out form to connect with our sales team.

4 Casing Dimensions

4 Casing Specifications

2480-N-CA

| 2488-CA

| 2488-E-CA

| 2496

| 2421

| 4596

| DH190 |

24112-E-CA

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

32112-CA

| 8063 |

535 |

9035 | 9036

| 9031 |

1013-1014 | 472

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4727

|

24104-R-CA

| AV30

| 24168-F-CA

| 24136-RF-CA

| 908

| 194

| AV4 |